γ-Alumina catalyst carrier for reforming

In reforming reactions, the choice of alumina (Al₂O₃) catalyst carrier shape depends on reaction mechanisms, mass transfer efficiency, pressure drop, and mechanical strength. Below are the commonly used carrier shapes and their applications:

Reforming Reactions

Objective: Convert naphtha into high-octane aromatics (e.g., BTX) or hydrogen, requiring metal active sites (Pt-Re/Pt-Sn).

Catalyst Characteristics: Requires high metal dispersion and stability (high temperature/pressure).

Common Carrier Shapes:

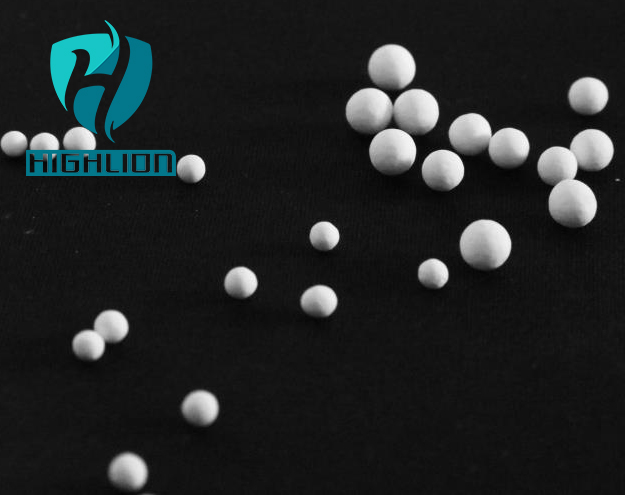

– Spherical (Spheres)

– Advantages: Low bed pressure drop, high mechanical strength, suitable for continuous catalytic reforming (e.g., UOP CCR Platforming).

– Typical Applications: Spherical γ-Al₂O₃ loaded with Pt-Re-Cl.

– Cylindrical (Extrudates)

– Advantages: Lower cost, used in semi-regenerative reforming (e.g., fixed-bed reactors).

– Applications: Small-to-medium-scale units or low-pressure processes.

Selection Rationale:

– Spherical carriers facilitate catalyst flow in continuous regeneration processes.

– Spheres exhibit better thermal stability at high temperatures, reducing wear.